Maintaining workplace safety is a priority for most truck repair shops, given the nature of their work. Dealing with heavy machinery, heavy-duty vehicles, various chemicals, power tools, electrical tools, and much more is enough of an indicator that there needs to be a stringent check on safety standards.

In addition to maintaining specific standards set by bodies like OSHA, our team here at BedLock Safety Products, LLC, also has some insights to share into this process, including the following dos and don’ts:

Don’t wear loose, ripped, or torn clothing on the job

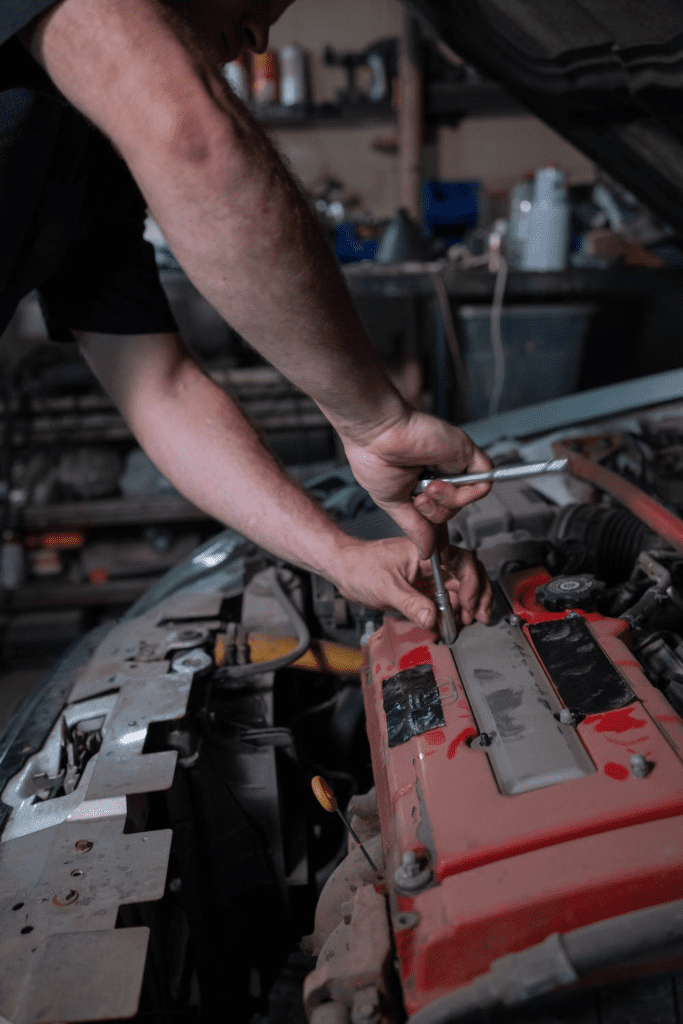

While it’s important to stay comfortable and wear breathable clothes that allow you to feel easy while working, you should not wear loose, ripped, or torn clothing while at your truck repair job. Clothes might get caught on machinery and hinges, while ripped or torn clothes may expose your skin to gasses, chemicals, and injuries from the impact. As a truck repair shop owner, it may be in your best interest to introduce uniforms.

Do always use protective gear and equipment, including vests

Ensure that your staff have access to and use safety gear and protective equipment, including vests, eye protection, and other essentials. These will keep them from coming in contact with unnecessary danger and help minimize the risk of injuries, burns, or exposure.

Don’t work without truck bed stands that ensure safety

If you haven’t gotten your hands on dump bed stands and other safety equipment from BedLock Safety Products, you’re missing out on greater efficiency and safety at your workplace. Always stabilize your machinery and get your dump beds and trailers upright using these stands, making more room to work, enjoying greater safety, and saving time and energy on work.

These stands also keep your workers safe from exertion and excessive time spent on manual labor.

Do ensure the ground is even, and the load is distributed evenly

However, when performing any maintenance or repair work and using stands to set your dump beds upright, ensure the ground below is fully even, and the load is fully distributed. This means checking tires to see they’re balanced, ensuring there are no slopes, tilting, or uneven pressure on either side for the best outcome possible.

Don’t leave keys in or keep your vehicles connected to power sources

Lastly, don’t forget to remove the keys and disconnect the power from the vehicle every single time. This is key to effective management and safety protocol at your truck repair workplace.

Maintain Workplace Safety Through Quality Safety Equipment for Trucks

The right safety equipment for trucks can make a world of difference when it comes to your service. Focusing on efficiency, productivity, and our range of stands and locks is ideal for your business. Contact our team at BedLock Safety Products, LLC, to invest in high-quality safety equipment and tools.