In the bustling world of logistics and transportation, trailers and trucks play a vital part in moving goods efficiently from one place to another. These heavy-duty vehicles are subject to constant wear and tear due to long hours on the road, heavy loads, and exposure to various weather conditions. Ensuring the safety and reliability of trucks and trailers is paramount, and that’s where preventative maintenance for trucks comes into play.

This blog explores why maintenance matters and our role as a truck safety equipment manufacturer.

Here’s Why Preventative Maintenance for Trucks Matters

Preventative truck maintenance involves a series of scheduled inspections, adjustments, and repairs to keep the vehicles in optimal working condition. Taking a proactive stance helps recognize and resolve potential concerns before they become significant issues. Fleet operators and truck owners can reap numerous benefits by adhering to a regular maintenance schedule.

Let’s take a closer look at these below:

Enhanced Safety

Regular maintenance checks identify safety hazards and ensure that critical components, such as brakes, tires, and steering systems, function properly. This reduces the risk of accidents from equipment failures.

Reduced Downtime

Unplanned breakdowns can result in significant downtime and loss of productivity. Preventative maintenance helps prevent unexpected breakdowns by detecting and addressing issues early, leading to increased operational uptime.

Extended Lifespan

Well-maintained trucks and trailers have a longer lifespan. By addressing minor problems promptly, you can avoid the need for significant repairs or premature replacements, saving both time and money.

Cost Savings

While preventative maintenance for trucks requires an upfront investment, it significantly reduces the likelihood of costly repairs. Regular servicing helps catch problems when they are manageable and less expensive.

Compliance

Trucks that undergo regular maintenance are more likely to meet regulatory and safety standards. This helps avoid fines and penalties for non-compliance.

Improved Fuel Efficiency

Well-maintained trucks operate more efficiently, leading to better fuel economy. This not only saves money but also reduces the impact on the environment.

Our Role At BedLock Safety Products, LLC

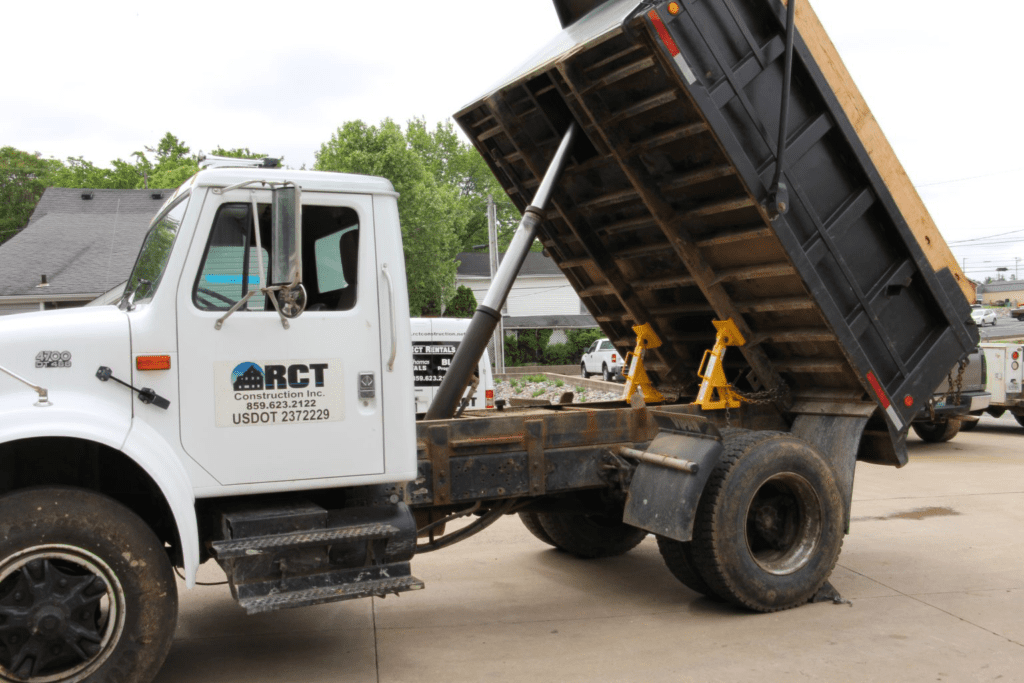

At BedLock Safety Products, LLC, we stand out as a pioneering force in truck repair safety equipment. Our innovative truck bed locks, dump bed safety supports, and dump body safety stands have revolutionized how trucks are maintained and repaired. Our commitment to ensuring the safety of maintenance personnel and preventing accidents aligns perfectly with the principles of preventative maintenance for trucks.

The Best Safety Equipment For Trucks, Made in Illinois

By utilizing BedLock Safety Products, LLC’s-safety equipment for trucks, including our dump truck safety braces and truck bed locks, you add an extra layer of protection to your maintenance routine. These products secure dump beds upright, allowing easy access and safe repairs. When your maintenance team can work without the fear of accidents caused by falling beds, productivity increases, and safety concerns are alleviated, creating a more positive and motivating atmosphere.

Contact us today to learn why we’re America’s safest truck repair safety equipment manufacturer and how you, too, can ensure dump truck repair safety through customized body safety props.